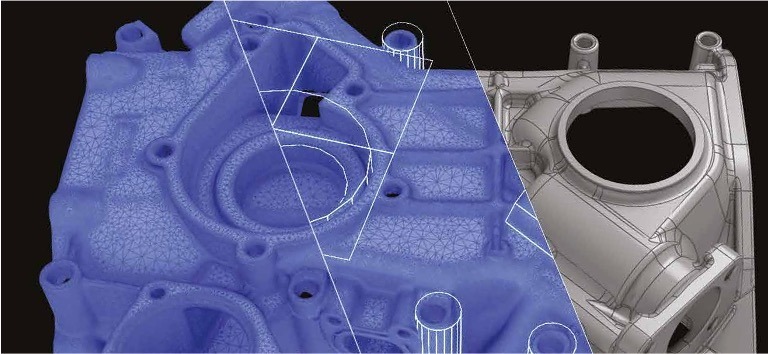

The task of replicating an original part, when the only information available is an old and normally broken casting, or a copy of a drawing that is hard to decipher, can be a long and arduous process. At Data 2 Patterns we can manage your projects from start to finish using our extensive foundry knowledge and “time compression technologies” to ensure your parts are correct and competitively priced. On receipt of a customers order and available information, a 3-dimensional CAD model is produced. This can be achieved by ‘scanning’ an original, plotting points from a casting part or by manual measure and CAD input. This model is then supplied to the customer in a usable format for verification.

- After any adjustments, the reversed engineered model is supplied to the foundry to ensure agreement on foundry method and price.

- Pattern equipment is then cut directly from the model data after agreement has been reached to its suitability.

The advantages of using Data 2 Patterns for your restoration work are:

- 2D to 3D conversion

- Verification of product prior to production

- Fine finish

- Attention to detail

- Extensive foundry knowledge

- Project management